KICI is non-profit second hand textile collector which funds many good causes with the profits they make form reselling second hand clothing. Most value is in the part of this clothing which is fashionably enough and of high enough quality. However, due to several socio-economical trends, the ratio of non-wearable clothing is growing each year. As this non-wearable part is currently not economically viable, a solution was wanted to increase the value of this waste stream.

(Note: Since then KICI has joined forces with a competitor Humana to form a company called Sympany)

The process of deconstruction non-wearable textile into (shorter) fibres is already common and is currently used to produce low-grade products such as insulation materials (image below on the right) or horse blankets. In most cases, non-wearable textie is sorted into three waste streams, according to the material types: cotton (first photo image below), acrylic-wool and polyester.

The core idea of this project was to take these recyled textile fibres and add some form of resin to construct a composite material. The assumption was that while adding materials and production costs, the added value increased in such a way, that bigger profit margins are possible. Both thermoplastic as thermosetting polymers were considered and tested as they both have specific pro’s and cons.

For both cases, all possible permutations were produced as samples and their strength was tested. A large number were not strong enough to be considered, but some showed much potential, especially the cotton based materials. The following plotos show some of the thermoplastic samples and the tensile strength testing.

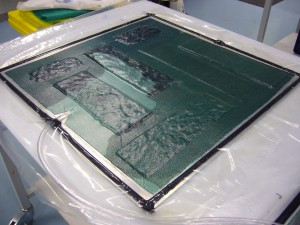

For this selection, larger samples were produced, to fine tune the fiber-polymer ratios, the the limits of the materials during production and improve the look and feel of these materials. The first image illustrates the process of a batch of fibres being infused by thermosetting resin. The second photo shows some denim (cotton) based samples, illustrating the effect of different polymers. Note that the fibres of the sample in the foreground have been torn in the production process, seriously reducing the strength of this sample.

The conclusion was that it is technically feasible to create thermoplastic and thermosetting composites based on (some) recycled textiles. However, the environmental imapct needed to be considered as wel. In order to prove the sustainability of these materials, a method developed at the TU Delft was applied, called the Ecocost Value Ratio (EVR, link to EVR website). Explaining this method here would lead too far, but based on a Life Cycle Analysis (LCA) of the materials, the assessment was made that beside financial benefits, these materials were also beneficial to reduce the impact on the environment compared to materials like MDF fibreboard.